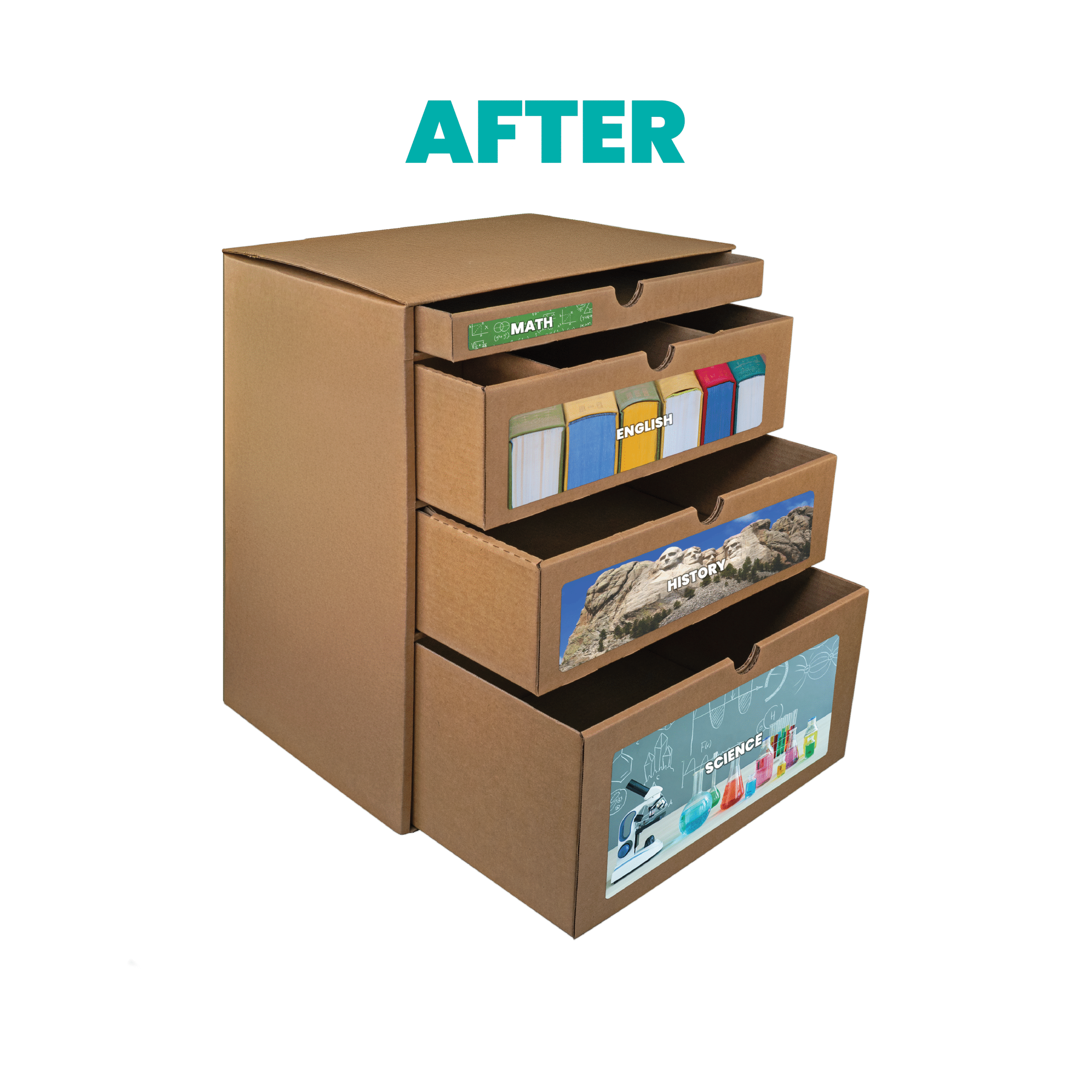

At Blink, STEM kit fulfillment isn’t just a service; it’s something we’ve built entire systems around. We’ve assembled more than 100,000 kits, shipped materials to classrooms in all 50 states, and supported over 280,000 classrooms and 8.4 million students with ready-to-teach science experiences. Every workflow we use was designed for accuracy, consistency, and speed, so teachers get exactly what they need when they need it.

We manage every part of the process under one roof. From sourcing components and producing printed materials to kitting, quality control, inventory management, and nationwide shipping, our team handles it all. Bringing every piece together in a single operation means fewer vendors, fewer handoffs, and far less room for error. Whether you’re launching a new curriculum or scaling an existing one, Blink ensures every kit is built the same way, every time.

Our process starts with understanding your curriculum inside and out. We break down every activity, prototype each kit, and customize assembly lines specifically for your materials. Kits then move through multi-stage quality checks — barcode scans, weight confirmations, inspections, and sign-offs — ensuring each one matches the exact requirements of your program. Once complete, we handle distribution to districts, warehouses, or directly to classrooms.

Across tens of thousands of builds, we’ve maintained a 99.8% accuracy rate, supported more than 1,000 unique SKUs, reduced plastic usage by 60%, and continually evolved packaging and processes to make kits easier for teachers and better for students. Blink isn’t just a fulfillment vendor — we operate as an extension of your team, delivering the consistency, reliability, and scale that national education programs require — and ultimately helping millions of students experience hands-on science the way it was meant to be taught.